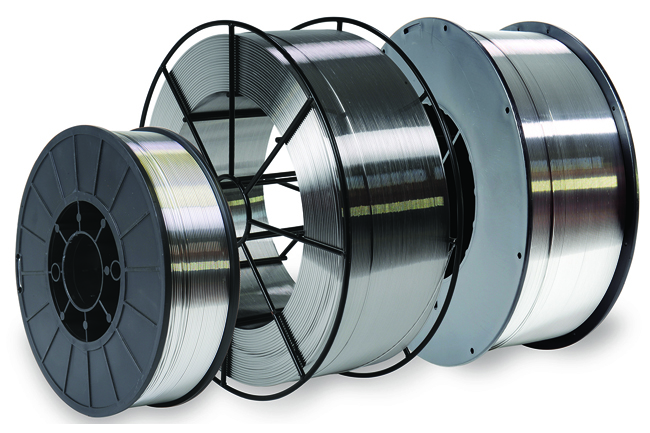

Gestión de Compras have the means to get a great variety of welding wire, for different compositions, dimensions and applications.

Product

Welding operation can be a significant fabrication activity for many companies, it is usually one of the first manufacturing processes to receive careful scrutiny when improve quality, raise productivity, and save costs is the goal. Unfortunately switch a lower cost wire or electrode could translate into additional money spent in pre- and post-weld operations such as cutting, forming, cleaning, tacking, grinding and painting, etc

Selecting a quality MIG wire is critical. It can be more forgiving and produce a sound weld even under less than perfect conditions. Take, for instance, a plate with surface contaminants. The right MIG wire for that application may make some pre-welding operations obsolete. And, as more companies move to robotics, a quality MIG wire will provide accuracy in wire placement and consistency in the weld, making rework less of an issue.

For this reasons in Gestión de Compras we offer different types of welding wires Depending on your requirements for quality, productivity and cost:

Standard and certificates

We have the means to ensure our products comply the general regulation and the specific certificated regulations in manufacturing products that requires them.

- ISO 9001

- ISO 14001.

- TS 16949,ISO 13485.

- OHSAS 18001.