Gestión de Compras have the means to get the parts manufactured by die-casting. We offer the most competitive products because we work with all materials and alloys and a wide range of processes.

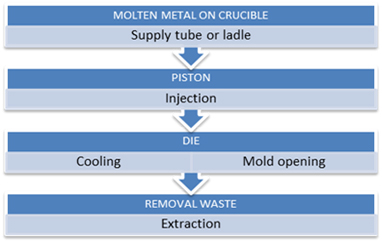

Process of Die casting

Die casting is a manufacturing process using large pressure to force the molten metal from the crucible, to the injection covering. After, hydraulic piston inject the molten metal to preformed mold (die). Once solidified the material, the piece is removed out of the mold. This process is used to produce whole parts or ingot.

Sometimes further treatments are necessaries after the die-casting in function of the casting or the metal we use: rough down the excess material casting, surface cleaning, heat treatment, machining, etc.

Our part are characterized by high uniformity, good surface finish and high dimensional accuracy. The dimensions of the parts can change in function of the requirement: Weights range from a few grams of the smaller pieces to several tons. We can obtain parts with extremely thin walled. In fact, most of the pieces don’t need final machining process or only need a very light machining.

Materials and products

We work with a wide range of materials:

-

- Grey iron casting

- Nodular cast iron

- All kinds of materials and non-ferrous alloys ( aluminium, zinc, copper, lead)

- Polymer and ceramic slurry

- Examples: 42CrMo4 (titan silver surface optional), G-X6CrNi 189, X5CrNi 18-10 SR…

Our main products:

-

- Automotive parts and machinery (clutches, gear boxes…)

- Valves, pipes and pipe fittings

- Parts for gasoline engines and air compressors

- Spare electrical and electronical

- Parts for lifts

- Aluminum parts

- Satellite receiver and miscellaneous

- In addition to CNC machining products obtained by casting

Tolerances

Dimensional tolerance depends on design specification. We usually work with 0.127 mm (0.005 inch.) in high requirements and other pieces which don’t need such a precise.

Standard and certificates

We have the means to ensure our products comply the general regulation and the specific certificated regulations in manufacturing products that requires them.

- ISO9001, TS16949 and ISO 14001

- QS9000, AS9100

- DIN 4766 for Surfaceroughness: N1, N2, N3 (precision tools, superfinishingbearings, polished surfaces), N4 (supports crankshafts and camshafts, hydraulicpower cylinder, lapped bearings, drive reducer, etc), N5, N6 (gear, bronze bearing), N7, N8 (bolt and bearing), N8

- DIN ISO 2768, DIN 1697, etc